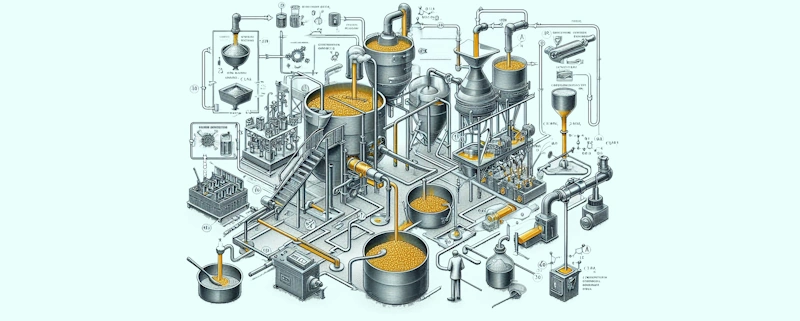

Gold refining is the process consisting in transforming raw gold into a pure, usable form, after removing all impurities and producing the highest possible quality of gold. This process is critical for various industries, particularly jewelry, electronics, and financial services, where high purity gold is required.

Gold refining techniques have evolved significantly over the centuries and millennia, transitioning from ancient methods to highly sophisticated modern technologies.

Historical Techniques

Gold refining dates back to ancient civilizations, where early the cultures of the Egyptians, Romans and Chinese began devising procedures for purifying gold. There are only two major ancient techniques:

Cupellation:: This ancient process was used to separate silver from gold. A very pure gold is melted in a special sort of porous container, (the cupel), and allowed to cool into the same. The lead, when heated in air to a possible temperature (above the melting point of gold or silver), is oxidized and absorbed into litharge, dispersing as well, leaving only pure metal. While an efficient method, cupellation was still insufficient for the extremely high standards of purity that are adhered to today.

Inquartation and parting: This process consists in alloying the gold with silver or copper to lower the purity, followed by treating the alloy with nitric acid or sulfuric acid. The acid works in dissolving the base metals to leave only pure gold. The approach, while easy enough in theory, nonetheless has a ceiling for purity.

Modern Refining Techniques

Modern techniques to refine gold have been taken over the years and made a considerable progress in order to produce gold at least 99.99% pure. The popular modern techniques that are used in modern time include:

The Miller Process (1897): The Miller Process is a relatively new process invented by Francis Bowyer Millar in 1867. This requires blowing chlorine gas through molten gold, where it reacts with impurities such as silver, lead and zinc forming chlorides with those metals that float to the surface in a process known as slag. Gold extracted by the Miller Process generally contains approximately 99.5% of gold.

The Wohlwill Process (1874): This method is named after Emil Wohlwill, but still in using nowadays as the most widespread way to refine gold. It consists in casting impure gold anodes which are suspended in an electrolyte solution of hydrochloric acid and gold chloride. When an electric current passes through the solution, pure gold is deposited onto cathodes. Gold of 99.9999% purity can be produced by the Wohlwill process which is quite considerable and superior to any other method of refining gold from the alloy at high scale with real swift turnaround time.

The Aqua Regia: A mixture of nitric acid and hydrochloric is used to dissolve gold. The solution is filtered and gold precipitates using a reducing agent like sodium bisulfite. Aqua regia is ideal for extracting gold from very high-value scrap, but must be neutralized, as it is particularly dangerous due to the acids.

Electrolytic Refining: This method is similar to the Wohlwill Process which involves placing impure gold into an acid solution (base) and then passing an electric current through it. This technique involves dissolving an impure gold anode into a solution and then plating the pure shiny metal on top of a cathode. This method is highly effective in producing high-purity gold and is often used in combination with other refining processes.

Environmental and economic effects

While contemporary methods of gold refining are quite effective, they lead to potential environmental and economic worries. There are also environmental risks to using some of these toxic chemicals, like chlorine and aqua regia. There are also questions about gold’s carbon footprint due to some energy-intensive refining processes, for example electrolytic refining.

As an alternative to crude oil, the industry has been investigating more sustainable means of refining these. For example, some firms are perfecting processes that employ less toxic chemicals (or cradle-to-cradle systems to minimise waste). There is a growing trend towards refining gold from recycled materials, which reduces the need for mining and its associated environmental impact.

Applications of Refined Gold

Gold is the key material used in various industries. There are several important cases amongst them, as follows:

The jewelry market is just one of the predominant customers for sophisticated gold. Fine jewelry is made from very high-quality (or pure) gold, and its value comes in the form of beauty, resiliency to damage to loss of finish.

Aside from ornaments and jewellery, gold being a good conductor of electricity, it is used for its excellent corrosion resistance for electronic applications. Gold is used to produce connectors, switches and other resilient electronic elements.

Gold traded in financial markets in a form of bullion is a fundamental aspect of modern global finance. Used to store as wealth (e.g., monetary reserves) and for direct payments. For investment purposes, high-purity gold is favoured because they are easier to standardize and verify.

Gold is used in dentistry because of its biocompatibility, resistance to corrosion and biological stability, unique properties that have no substitute in several dental applications, like dental restorations, and some surgical instruments also contain refined gold.

What the future holds for gold refining

There is much likelihood that the gold refining industry will be undergoing further innovations in years to come. Stricter environmental regulations will drive the development of eco-refineries taking minimal toll on their surroundings. R&D activities on efficient refining processes using less energy and producing less waste may also improve due to technology advances.

The final trend likely to gain popularity is the emphasis on traceability in gold refilling. Gold that can be tracked all the way back to mines which are environmentally and socially-responsible suits those who buy gold coins or take gold as an investment.

Gold refining is a sophisticated and important process that has developed over thousands of years. From long outdated practices of cupellation and parting to more recent developments in techniques such as the Miller Process, or even the Wohlwill process. The quest for purity has been a driving force behind major technological leaps.

In the greening of gold refining itself, broader industry trends pushing it towards cleaner and more equitable processes and operations are going to then determine its future. Be it for ornaments, for electronic applications or to invest in gold, this refined gold produced using these patented techniques will continue its crucial role as an economic and social backbone.